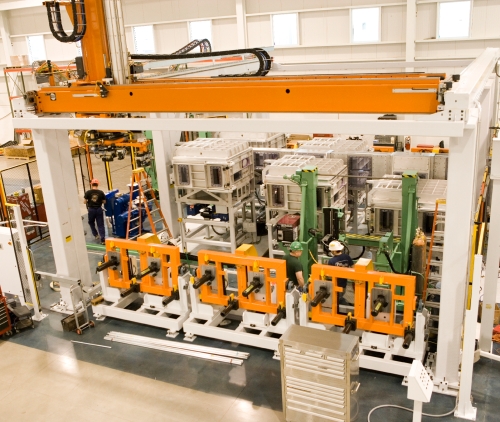

photos: Energy Conversion Devices

As Detroit automakers shutter SUV and truck factories, the decades-long de-industrialization of the Midwest continues apace. But amid the idled assembly lines, a new wave of manufacturing has taken root as solar energy companies set up shop in the heartland.

Just in the past week, First Solar (FSLR) announced an expansion of its Ohio plant that makes thin-film solar panels. German company Flabeg will break ground on a factory outside Pittsburgh that will manufacture parabolic solar mirrors for large-scale solar power plants planned for the Southwest. Thin-film solar company Energy Conversion Devices (ENER), meanwhile, operates three factories in Michigan and is currently doubling the production capacity of one of its plants.

In fact, nearly all the United States’ current solar manufacturing capacity is in the Midwest, save for Silicon Valley company Ausra’s factory in Las Vegas. (Thin-film startup Nanosolar is building a factory in San Jose, Calif.)

“Our processes really require high productivity, so what makes it competitive here in the Midwest is that we have a great labor force that is eager to work and well-trained already,” ECD chief executive Mark Morelli told Green Wombat on Monday.

“Our processes really require high productivity, so what makes it competitive here in the Midwest is that we have a great labor force that is eager to work and well-trained already,” ECD chief executive Mark Morelli told Green Wombat on Monday.

For instance, when appliance maker Electrolux shut down its Greenville, Mich., factory it left 2,700 workers unemployed in the same town where ECD is expanding its thin-film factory (see photos). The company also has recruited top executives from the ever-shrinking auto industry.

“We do a test of the available labor pool and hire the cream of the crop,” Morelli says.

Just as important are a plethora of state tax breaks and grants to retrain industrial workers for the green tech economy.

Although 70 percent of ECD’s flexible solar laminate panels are sold to European customers, Morelli anticipates the U.S. market will take off, with domestic manufacturers garnering a competitive advantage.

That all depends on whether Congress extends a crucial investment tax credit that expires this year and the policies of the next administration in Washington. Even so, demand for solar cells is expected to spike, especially given the recent unveiling of Big Solar projects by California utilities. Southern California Edison (EIX), for instance, is installing 250-megawatts’ worth of solar panels on commercial rooftops while PG&E (PCG) this month announced contracts to buy 800 megawatts of electricity from two photovoltaic power plants, including 500-megawatt thin-film solar farm being built by OptiSolar.

“As utilities begin to embrace distributed power generation, these type of things play into our natural advantage,” says Morelli, referring to his company’s lightweight solar panels that are especially suited for large rooftop arrays.

Of course, a handful of solar factories are not going to revive the Midwest’s industrial fortunes. (First Solar, for instance, operates factories in Germany and Malaysia, and Morelli doesn’t rule out locating manufacturing overseas.) But imagine a national policy that promotes the wide adoption of solar and the expansion of manufacturing in the rustbelt states becomes increasingly attractive. Shipping solar panels and mirror arrays from halfway around the world starts to make much less environmental and financial sense.

ECD’s proximity to the auto industry has already paid off. After installing solar arrays on two of General Motors (GM)’s California facilities, it won a contract in July to build a 12-megawatt rooftop array – the world’s largest by orders of magnitude – at a GM assembly plant in Spain.