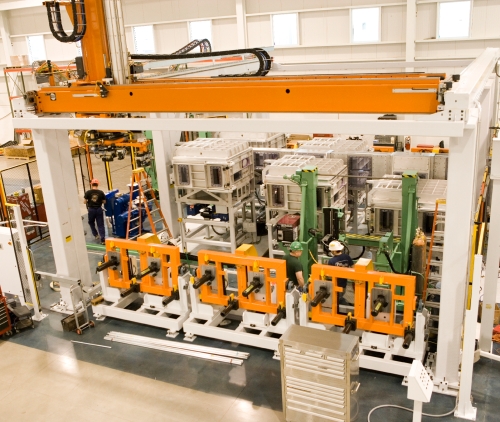

photo: David Lena

In a move that could alter the economics of the global solar industry, California utility PG&E on Thursday announced that it will buy 800 megawatts of electricity produced from two massive photovoltaic power plants to be built in San Luis Obsipo County on the state’s central coast. The 550-megawatt thin-film plant from Bay Area startup OptiSolar and a 250-megawatt PV plant from Silicon Valley’s SunPower dwarf by orders of magnitude the five-to-15 megawatt photovoltaic power stations currently in operation around the world.

Most of the industrial-scale solar plants designed to replace fossil-fuel power use solar thermal technology, meaning they deploy mirrors to heat liquids to produce steam that drives electricity-generating turbines. Photovoltaic power plants essentially take the solar panels found on suburban rooftops and put them on the ground in gigantic arrays. How gigantic? OptiSolar’s Topaz Solar Farm will cover 9 1/2 square miles of ranch land with thin-film panels like the ones in the photo above. Combined, the two solar plants would produce enough electricity to power 239,000 California households, according to PG&E (PCG).

“Obviously this is huge and a bold move,” says Reese Tisdale, a senior analyst who studies the economics of solar power for Emerging Energy Research in Cambridge, Mass. “It’s a pretty big jump in manufacturing capacity and a big opportunity for the PV industry, particularly for thin-film.”

If the power plants are ultimately built – and that’s a big if, given the challenges to get such facilities online – and other utilities follow PG&E’s lead, demand for solar modules could skyrocket. (Thin-film cells like those made by OptiSolar are deposited or printed in layers on glass or flexible metals. They are less efficient at converting sunlight into electricity than standard solar modules but they use far less expensive polysilicon and can be produced much more cheaply.)

First Solar (FSLR), a leading thin-film maker, has an annual manufacturing capacity of around 275 megawatts – which will rise to a gigawatt by the end of 2009. (First Solar is building two small-scale solar power plants for Southern California Edison (EIX) and Sempra (SRE).) SunPower (SPWR) is expected to produce 250 megawatts worth of solar modules this year; its California Valley Solar Ranch project for PG&E alone will be consume 250 megawatts.

“If we were trying to do it this year, it would be all of our production,” says Julie Blunden, SunPower’s vice president for public policy. “SunPower is ramping very quickly. By 2010 our production will be at least 650 megawatts.” SunPower’s solar power plant is set to begin producing electricity in 2010.

The PG&E deal puts OptiSolar in the spotlight. Founded by veterans of the Canadian oil sands industry, the stealth Hayward, Calif., startup has kept its operations under cover, avoiding the media as it quietly set up a manufacturing plant in the East Bay and prepared to break ground on a million-square-foot factory in Sacramento.

OptiSolar CEO Randy Goldstein told Green Wombat that the company will have no problem producing enough solar cells to build Topaz, which is scheduled to go online in 2011, as well as fulfill contracts for some 20 small-scale power plants in Canada.

“Our plan has always been to produce solar energy on a very large scale to make it cost-competitive, even in a market like California,” Goldstein says.

The terms of utility power purchase agreements like the ones OptiSolar and SunPower have signed with PG&E are closely held secrets, but it has long been an open secret that building massive photovoltaic power plants was not economically viable. Last year when I attended the opening of an 11-megawatt PV power station in Portugal – which offers generous solar subsidies – that was built by SunPower’s PowerLight subsidiary, PowerLight’s CEO told me that pursuing such projects in the U.S. was not an attractive proposition due to market incentives and public policy.

So what has changed too make constructing gargantuan PV power plants profitable?

“Lots of things have changed,” says SunPower’s Blunden. “Power prices are going up and public policy is requiring utilities to have a portfolio of renewables.” And after building some 40 megawatts of power plants in Spain, SunPower has been able to improve its manufacturing processes and cut costs, according to Blunden. “We could see where the cost reductions were coming down and the benefits of scale,” she says. “We saw there was a way for us to be competitive with other renewables.”

Goldstein says OptiSolar’s business model of owning the supply chain – from building its own machines to make solar cells to constructing, owning and operating power plants – will allow it to reduce costs. “By taking control of the value chain from start to finish, by being vertically integrated and cutting out the middleman,” he says, “we can be competitive not only with other renewable energy but with conventional energy.”

Photovoltaic power plants do have certain advantages over their solar thermal cousins. They don’t need to be built in the desert, thus avoiding the land rush now underway in the Mojave. PV is a solid-state technology and with no moving parts – other than the sun tracking devices used in some plants – they make little noise and are relatively unobtrusive. Most importantly in drought-stricken California, they consume minimal water. And the modular nature of solar panels means that a power plant can start producing electricity in stages rather after the entire facility has been constructed.

“The economies of scale does make PV cost competitive with other renewable energy generating technologies, and wouldn’t be possible without advances that SunPower and OptiSolar have been working on,” says PG&E spokeswoman Jennifer Zerwer. “We take a stringent look at all technologies and we’re not wedded to a particular one.”

With the PV plants, PG&E now has contracts to obtain 24 percent of its electricity from renewable sources.

But contracts are no guarantee the even a watt will be generated. The Topaz and California Valley projects must overcome a number of obstacles, not the least of which is the U.S. Congress’ failure so far to extend a crucial 30 percent investment tax credit for solar projects that expires at the end of the year. SunPower’s Blunden acknowledges the PG&E project is contingent on the tax credit being renewed.

PG&E executive Fong Wan said as much at a press conference Thursday afternoon: “That is a major hurdle. If the investment tax credit is not extended, I expect many of our projects will be delayed.”

Then there’s the question of how welcoming rural San Luis Obispo County residents will be to two massive solar power plants in the neighborhood. Along with a 177-megawatt solar thermal power plant being built by Silicon Valley startup Ausra for PG&E adjacent to the Topaz project, the county has become a solar hot spot. Ausra has run into some community opposition and state officials are growing concerned about the impact of the power plants on protected wildlife.

“The challenge is going to be the magnitude of these projects,” says Tisdale, the energy analyst. “Other projects are already facing opposition from the environmentalists.”

But for solar power companies like OptiSolar the impetus is to get big and get big fast. “I think it’s going to demonstrate that photovoltaics have the ability to be part of the energy mix,” says Goldstein of Topaz. “We can scale up and have a big impact. There’s not going to be a lot of room for niche players in the long run.”

Read Full Post »

Bigger turbines offer better economies of scale (important given the steep cost of developing offshore wind farms), and since a deep-ocean wind turbine is not visible from the coast, they avoid the not-in-my-backyard fights that dog near-shore projects. (Clipper Windpower of Carpinteria, Calif., is developing a ten-megawatt monster for England’s Crown Estate, while European wind companies like Enercon has been testing turbines in the six megawatt range.)

Bigger turbines offer better economies of scale (important given the steep cost of developing offshore wind farms), and since a deep-ocean wind turbine is not visible from the coast, they avoid the not-in-my-backyard fights that dog near-shore projects. (Clipper Windpower of Carpinteria, Calif., is developing a ten-megawatt monster for England’s Crown Estate, while European wind companies like Enercon has been testing turbines in the six megawatt range.)

“Our processes really require high productivity, so what makes it competitive here in the Midwest is that we have a great labor force that is eager to work and well-trained already,” ECD chief executive Mark Morelli told Green Wombat on Monday.

“Our processes really require high productivity, so what makes it competitive here in the Midwest is that we have a great labor force that is eager to work and well-trained already,” ECD chief executive Mark Morelli told Green Wombat on Monday.